Tel:

18851697216

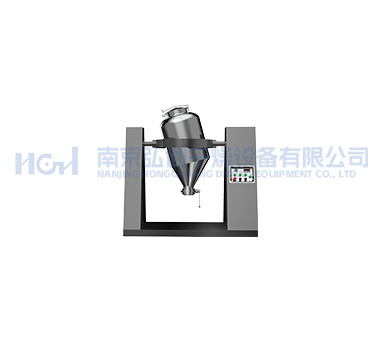

SPH type three eccentric mixer

Online:

Phone:18851697216

Tel:025-85704510

- Characteristic

- Parameter

- Relevant

Working principle

Adopting the principle of three eccentricities, namely the center of gravity eccentricity, axial eccentricity, and upper and lower eccentricity of the barrel, combined with a six directional asymmetric design, the material undergoes complex multi-directional displacement and cross motion during the mixing process, achieving uniform mixing.

Performance advantages

High mixing efficiency: large mixing capacity, high loading factor, short mixing time, and high mixing uniformity.

? Stable operation: The equipment runs smoothly, with low noise, simple maintenance, low repair costs, and energy efficiency.

Strong adaptability: Suitable for material mixing in industries such as pharmaceuticals, food, chemicals, ceramics, plastics, etc., especially suitable for powdered materials with humidity, softness, and varying specific gravity.

? Easy to operate: Easy to feed and unload, stepless frequency conversion speed regulation, complete control system functions, easy to operate.

Safe and reliable: The equipment complies with GMP standards, and some models are equipped with infrared safety controls to ensure safe operation.

technological innovation

Effectively addressing the demand for high-capacity, high-efficiency, and low-cost hybrid equipment, it has the advantages of small size and large capacity.

Some three eccentric mixers have online cleaning function, which ensures thorough cleaning, easy operation, and leaves no dead corners.

Some three eccentric mixers are designed with a powder cleaning mechanism, which can quickly clean the powder attached to the inner wall of the mixer and avoid contamination.

Market and Application

Widely used for material mixing in industries such as pharmaceuticals, food, chemicals, ceramics, plastics, etc., to meet the mixing needs of different industries.

The three eccentric mixer, with its unique design and excellent performance, has been widely used and recognized in the field of material mixing, providing efficient and reliable mixing solutions for various industries.

Type

SPH-1m3

SPH-2m3

SPH-3m3

SPH-4m3

SPH-5m3

SPH-6m3

SPH-8m3

SPH-10m3

SPH-12m3

SPH-15m3

Mixing bucket capacity(M3)

1

2

3

4

5

6

8

10

12

15

Charge(M3)

0.75

1.5

2.25

3

3.75

4.5

6

7.5

9

11.25

Hybrid motor power(KW)

4

5.5

5.5

7.5

7.5

11

15

15

18.5

22

Rotational speed(r/min)

12

12

10

10

8

7

7

6

6

5

Specification of discharge butterfly valve(mm)

Φ200

Φ200

Φ250

Φ250

Φ300

Φ300

Φ300

Φ300

Φ300

Φ300

Cylinder rotation height(mm)

2600

3100

3600

3700

4000

4400

4600

5100

5600

7000

Center height of shaft end(mm)

1600

1900

2100

2300

2400

2550

2750

2920

3170

3430

Cylinder turning radius(mm)

1950

2500

2950

3200

3510

3640

4120

4440

4690

4900

External dimensions(mm)

2900×1450

3520×1600

3780×1600

4220×1700

4500×1750

4740×1850

5100×2250

5500×2400

5700×2450

6000×2600

The height of the discharge butterfly above the ground(mm)

600

-

Working principle

Adopting the principle of three eccentricities, namely the center of gravity eccentricity, axial eccentricity, and upper and lower eccentricity of the barrel, combined with a six directional asymmetric design, the material undergoes complex multi-directional displacement and cross motion during the mixing process, achieving uniform mixing.

Performance advantages

High mixing efficiency: large mixing capacity, high loading factor, short mixing time, and high mixing uniformity.

? Stable operation: The equipment runs smoothly, with low noise, simple maintenance, low repair costs, and energy efficiency.

Strong adaptability: Suitable for material mixing in industries such as pharmaceuticals, food, chemicals, ceramics, plastics, etc., especially suitable for powdered materials with humidity, softness, and varying specific gravity.

? Easy to operate: Easy to feed and unload, stepless frequency conversion speed regulation, complete control system functions, easy to operate.

Safe and reliable: The equipment complies with GMP standards, and some models are equipped with infrared safety controls to ensure safe operation.

technological innovation

Effectively addressing the demand for high-capacity, high-efficiency, and low-cost hybrid equipment, it has the advantages of small size and large capacity.

Some three eccentric mixers have online cleaning function, which ensures thorough cleaning, easy operation, and leaves no dead corners.

Some three eccentric mixers are designed with a powder cleaning mechanism, which can quickly clean the powder attached to the inner wall of the mixer and avoid contamination.

Market and Application

Widely used for material mixing in industries such as pharmaceuticals, food, chemicals, ceramics, plastics, etc., to meet the mixing needs of different industries.

The three eccentric mixer, with its unique design and excellent performance, has been widely used and recognized in the field of material mixing, providing efficient and reliable mixing solutions for various industries.

Copyright Nanjing Hongchuang Drying Equipment Co., Ltd All Right

中文版

中文版 English

English